SMC Unifit Threads

Wednesday, October 14, 2020 12:47:52 PM America/New_York

Inventory maintenance is one of the most challenging issues facing machine builders. Having hundreds of part numbers and multiple variations of the same or very similar parts add to the complexity of inventory maintenance. Solving issues like this has been a major objective for SMC.

Inventory maintenance is one of the most challenging issues facing machine builders. Having hundreds of part numbers and multiple variations of the same or very similar parts add to the complexity of inventory maintenance. Solving issues like this has been a major objective for SMC.

Maintaining the correct number of spare fittings on hand for thread types is complicated. SMC has developed a unique solution to eliminate thread issues encountered by machine builders. SMC’s Unifit fittings work on multiple thread types and allow you to stock fewer fittings while ensuring you have the correct fittings available to keep your machines working properly and efficiently. SMC Unifit one-touch fittings have been designed to thread and seal properly into NPT, NPTF, Rc, R(PT), BSPT, G, or BSPP female threads.

SMC Unifit fittings have a conical rubber seal on the threaded side. They work by lightly threading into the female end and then fully sealing with a quarter turn of a wrench. This is beneficial because machine builders will not have to inventory multiple fittings to match certain threads but can use SMC Unifit fittings to reduce part numbers.

SMC Unifit fittings have a conical rubber seal on the threaded side. They work by lightly threading into the female end and then fully sealing with a quarter turn of a wrench. This is beneficial because machine builders will not have to inventory multiple fittings to match certain threads but can use SMC Unifit fittings to reduce part numbers.

As documented on the Hydraulics and Pneumatics website, “By using fittings with the unifit thread, tubing can be connected to parts which use parallel as well as taper-type threads in British Standard Pipe as well as National Pipe Thread (US standard). Assembly times can be reportedly be cut by around 75%, freeing up maintenance engineers to focus on pressing issues. The seal is made by an NBR laminated stainless steel gasket and is suitable for all female threads with a standard 45-degree chamfer; this feature also minimizes the risk of contamination, and a consistent height can be achieved when fitting into a manifold. In addition, because the unifit seals on a gasket rather than on the fitting’s thread, the overall installation height of the fitting is reduced.”

Additionally, SMC Unifit fittings can be re-used many times allowing users to cut their operating costs.

MORE ABOUT THREADS

Threads are complicated. In fluid power all threads have a common goal, to make a leak free connection for the media traveling through the pipe. Ensuring that you are using the correct type of thread is critical for proper mating. Additionally, using the proper threads prevent costly and time-consuming thread stripping and damage.

For years in America, the pneumatic systems in the US primarily used NPT/NPTF threads (NPT/NPTF) and SAE or Unified threads (UN/UNF) for smaller connections. Today with industrial machinery coming into the US from abroad and US machinery manufacturers supplying their machines to overseas markets, the popularity of metric threads has increased.

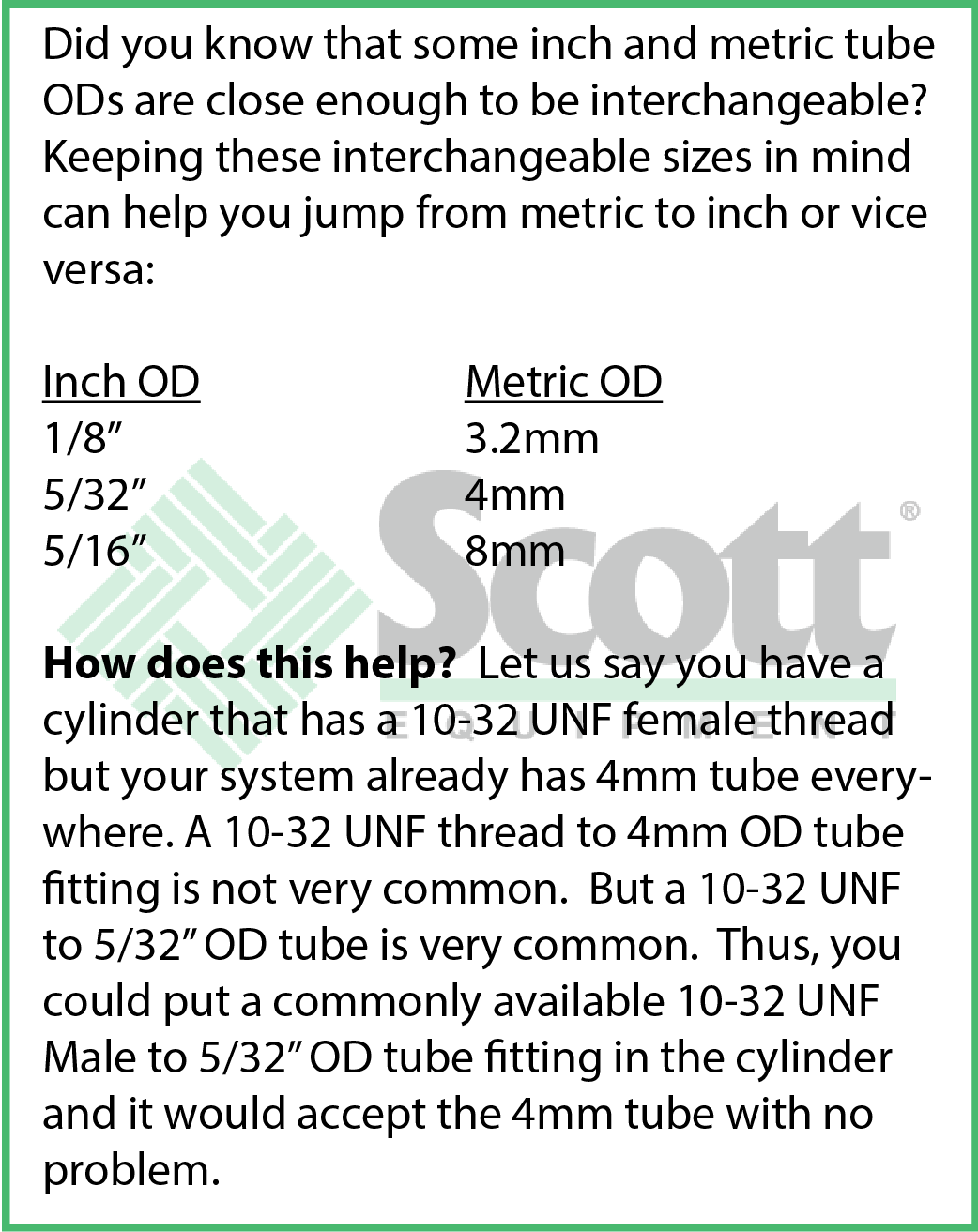

To add on to the complexity, in pneumatics, many of these threaded connections are in fittings used to connect to pneumatic tubing which is available in both metric and inch size OD. It is not uncommon anymore, to encounter a need to connect a Rc cylinder or valve port to an inch OD tube or vice versa. To do this without a stack of adapters is relatively easy with a little knowledge of threads.

To add on to the complexity, in pneumatics, many of these threaded connections are in fittings used to connect to pneumatic tubing which is available in both metric and inch size OD. It is not uncommon anymore, to encounter a need to connect a Rc cylinder or valve port to an inch OD tube or vice versa. To do this without a stack of adapters is relatively easy with a little knowledge of threads.

Why is this important?

Today pneumatic fittings and connectors can be divided into five different thread types:

- NPT / NPTF – National Pipe Thread American Standard According to ANSI/ASME B 1.20.1. The NPT/NPTF tapered thread type is used interchangeably in pneumatics up to ½” NPT (above ½” NPT and NPTF threads are not interchangeable). To get a proper pneumatic seal with this thread Teflon,™ tape or pneumatic sealant like Loctite™ 554 must be applied to the male thread.

- Rc (also known as R(PT) and BSPT) - Tapered thread connection according to ISO7/1. To get a proper pneumatic seal with this thread Teflon,™ tape or pneumatic sealant like Loctite™ 554 must be applied to the male thread. Keep in mind a Rc male thread will seat and seal (with tape or sealant) into a female G thread. But a G thread male will not thread into an Rc female.

- G (also known as BSPP) – Parallel thread type according to ISO 228/1. This thread depends on a face seal but does thread in flush and does not require sealant or tape.

- UNF – Parallel thread type according to ISO 68, ANSI B1.1. This thread type is very common in hydraulics in many sizes and only commonly used in pneumatics for smaller connections (e.g., 10-32 UNF). This thread depends on a face seal or crush washer to seal the connection. It does make a flush connection.

- M – Parallel threads according to ISO 68/ISO 724. This thread type is similar in use to UNF in pneumatics. In pneumatics it is primarily found in smaller thread types (e.g., M5, M3). The most common UNF thread in pneumatics 10-32 UNF, and the most common M thread in pneumatics M5 have some compatibility. A 10-32 UNF male will thread into a M5 female, but a M5 male will not thread into a 10-32 UNF female.

How to Identify Threads

- Determine if the thread is tapered or parallel. Tapered threads get smaller in diameter toward the end of the fitting while parallel threads have the same diameter from end to end. An O-ring, face seal, or crush washer usually indicates parallel threads.

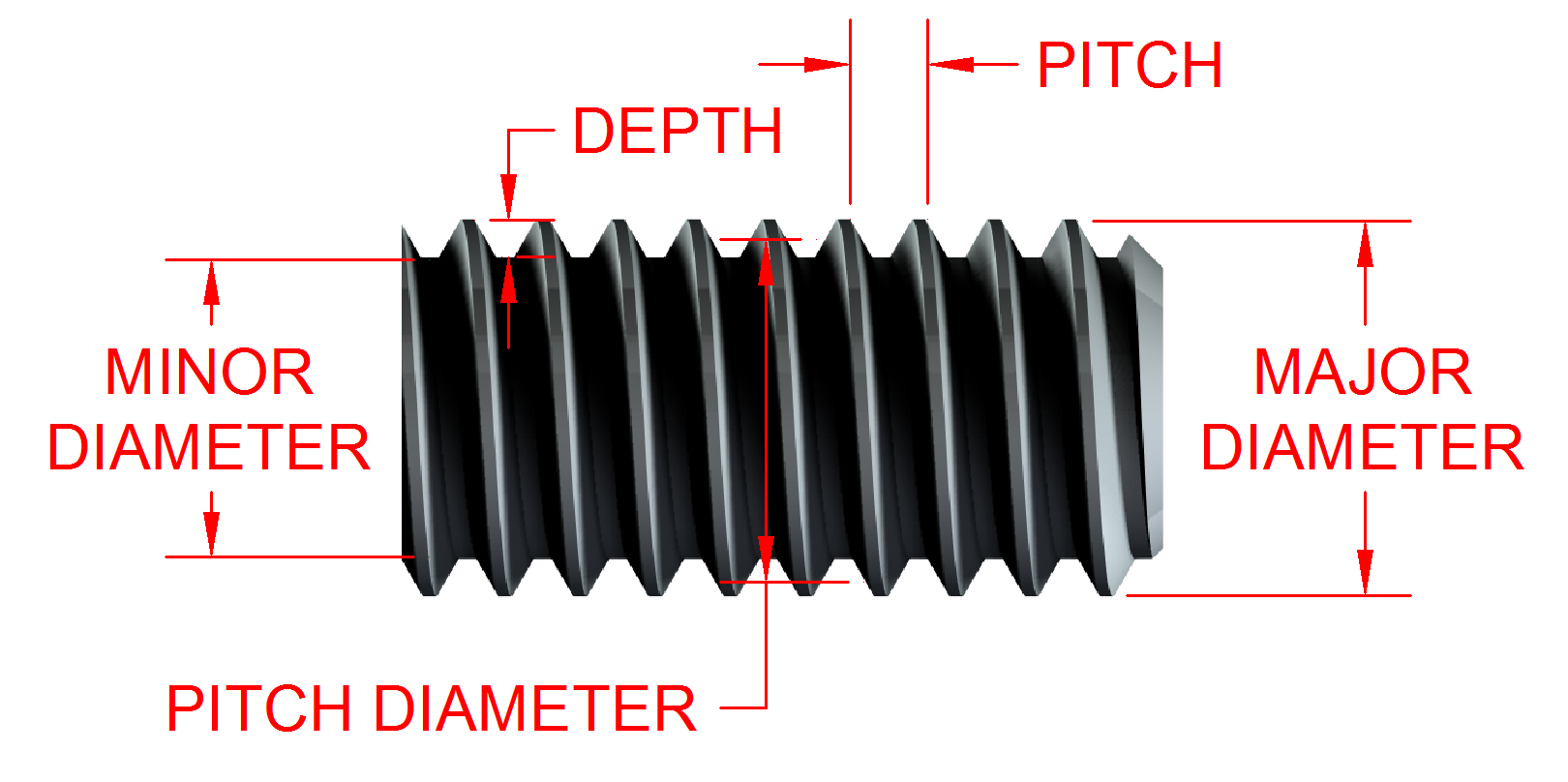

- Determine pitch. Pitch is typically defined in terms of threads per inch (TPI) or distance between threads. For metric threads, pitch is the distance between threads in millimeters. The best way to determine pitch is to use a pitch gauge. Another way is to accurately measure and calculate the number of threads within a given length.

- Determine size. To determine thread size, you must determine if the threads are pipe or non-pipe. For pipe threads, determine nominal size by comparing the part against a size profile by taking measurements of the OD or ID with calipers. Compare these measurements with thread identification reference tables.

Thread Cheat Sheet and Notes:

NPT and NPTF are the same and compatible in pneumatics in sizes up to ½”

Rc, R(PT) and BSPT are the same.

G and BSPP are the same.

A Rc thread male will go into a G thread female and seal correctly.

A G thread male will NOT go into a Rc female. Why: A Rc thread is a tapered thread meaning it screws in until it interferes and cannot go any more and seals. A G thread is a parallel thread with means it must go all the way in and seals on a washer that is pressed down on a flat surface.

UNF and Metric threads are typically found in small components. A 10-32 UNF will thread into a M5 female but an M5 male will not thread into a 10-32 UNF female thread. NOTE: UNF and M threads are not NPT, G or R(PT).

A SMC unfit male fitting will thread into NPT, NPTF, Rc, R(PT), BSPT, G, or BSPP female threads.

Ask your Account Manager about getting one of our Scott Equipment Tube Gauges that contains these tips as well as tools to assist you in measuring!

More SMC blog posts:

SMC - Addition of NFPA Standard Threads

SMC Positive Pressure Sensors & Switches

SMC JSXFA Plus Valves for Dust Collectors

SMC Best Practices - Remove Water from Factory Air and Minimize Costly Downtime