SMC MACM Centering Unit

Friday, April 20, 2018 2:29:29 PM America/New_York

SMC's new MACM centering unit contributes to space sa

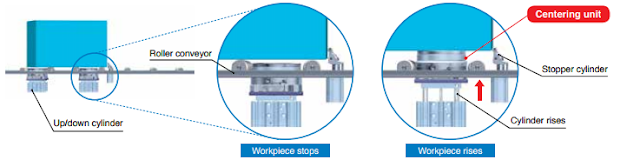

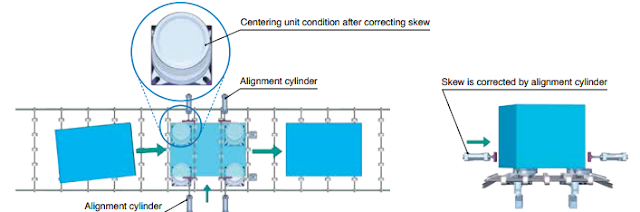

SMC's new MACM centering unit contributes to space sa ving on conveyor lines. Heavy workpieces can now be aligned and positioned with small cylinders, resulting in compact conveyor lines.

ving on conveyor lines. Heavy workpieces can now be aligned and positioned with small cylinders, resulting in compact conveyor lines.

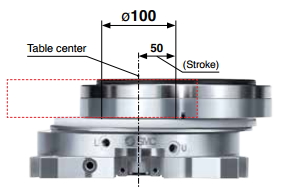

Workpieces can be moved in any direction: forward/backward, right/left, at an angle, and even rotated (360 degrees). Ball bearings allow for smooth operation. Table center has a moveable range of 100mm Max (MACM10-50) with a maximum allowable load weight of 2205 lbs.

|

|

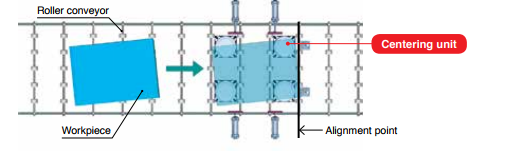

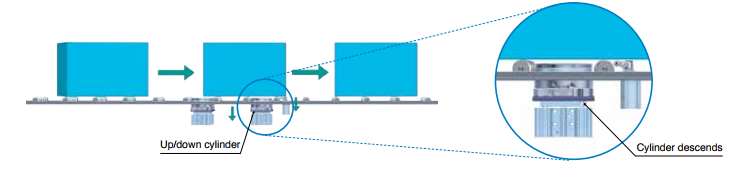

Application Example: Conveyor Line

Contact us today for more information.

More SMC blog posts:

SMC - Addition of NFPA Standard Threads

SMC Positive Pressure Sensors & Switches

SMC JSXFA Plus Valves for Dust Collectors

SMC Best Practices - Remove Water from Factory Air and Minimize Costly Downtime