SMC Air Management System (AMS) - New Product Alert

Wednesday, September 28, 2022 3:00:33 PM America/New_York

Keeping an eye on sustainability, predictive maintenance and digitilization is always at the forefront in industrial environments. Whether it is a manufacturing or packaging facility, having a system to monitor pneumatic automation systems and ensure that everything is operating as efficiently as possible is extremely important.

Keeping an eye on sustainability, predictive maintenance and digitilization is always at the forefront in industrial environments. Whether it is a manufacturing or packaging facility, having a system to monitor pneumatic automation systems and ensure that everything is operating as efficiently as possible is extremely important.

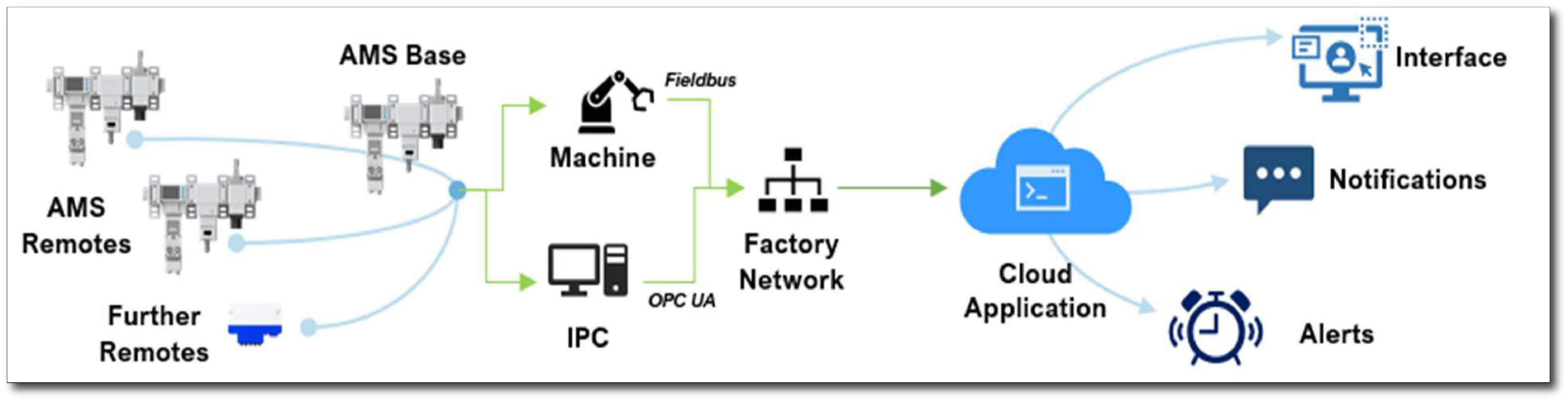

To help with this scenario, SMC has developed an Air Management System (AMS) that allows users to monitor their systems by gathering data allowing them to develop energy savings plans. SMC’s AMS constantly measures the system’s air pressure, flow, and temperature measurements. Using the data that is collected, air leaks can be identified, and the overall performance of the application can be analyzed to optimize operation.

SMC’s AMS uses standard M12 connections and has both IO-Link & digital inputs. Additionally, the AMS uses a secure 100m proprietary wireless transmission protocol that reduces wiring and eases installation. The AMS can also be implemented in challenging environments because it has IP67 ingress protection.

SMC’s AMS supports AI based analytics allowing the user to visualize real time information. AMS can display the following:

- Identify abnormal flow and pressure

- Display the machine status as running, paused, or stopped

- Develop detailed fingerprints about the machine operation

- Customized maintenance alerts for CMMs systems

- Agnostic data integration (works with 3rd party analytics0 @10 Hz

SMC’s AMS is easy to install. AMS devices can be installed irrespective of machinery age and instantly start gathering data. The system doesn’t require any PLC editing and is essentially plug and play. AMS allows users to establish best practices through the baselining of individual machines. And the system is scalable – up to 10 wireless standalone remotes to one base unit. Data can be collected from connected external sensors via IO-Link or discreetly direct to AMS Hub or remote.

In addition to monitoring the system, AMS allows users to utilize “Eco-mode” during periods of dwell and rest to proactively and automatically reduce air consumption and leakage rates using AMS standby mode. SMC AMS can also automatically optimize compressed air use when machines are inactive for long periods of time by using isolation mode.

SMC AMS COMPONENTS

AMS Hub/Remote

- Fieldbus – Profinet, Ethernet IP, EtherCAT

- OPC USA Server (Hub)

- Wireless connectivity with 100m range

- 4 or 8 IO-Link or discrete I/O

- Color Information Centre

- Programming and display setting keys

- M12 Connectors

- Wireless Adaptor for enclosed spaces

- 4 Sizes: 0-500, 0-1,000, 0-2,000, 0-4000 l/min

- Monitors pressure between 0 and 1.0MPa (0 to 10Bar)

Electropneumatic Regulator

- N.C. or N.O. configurations are available

- Regulates the Working Pressure

- Regulates the “eco” Standby Pressure

- Soft Start capability

- 4 sizes available across ¼” to 1” ports

Manual Standby Regulator

- Locking knob to set “eco” Standby Pressure

- M12 connector

- NO at idle

- 4 sizes

Shut off Valve

- N.C. or N.O. configurations are available

- Provide a long-term isolation

- Soft Start for Controlled initialization

- 4 sizes available across ¼” to 1” ports