Robotic Tool Changers

Friday, April 8, 2022 11:20:57 AM America/New_York

As robotic automation is becoming more attainable and easier to program, reprogram and repurpose, it is not unheard of to have a larger wish list of what robots can accomplish. One of the biggest challenges with robotic applications is speed and efficiency. A popular solution to solve this challenge is either automatic or manual tool changers. Tool changers are devices designed to allow the to robot to quickly change their end-effectors to accomplish different jobs without human intervention.

For example, on a typical production line, workers are required to complete a number of tasks using specialized tools. The worker will complete one task and then have to pick up a new tool for the next task and so on. Using tool changers on the end of a robot allows the process to be automated.

Some typical tool changer applications include:

Some typical tool changer applications include:

Machine Tending: A tool changer allows the robot to swap grippers between machine operations.

Palletizing: When palletizing products that require different handling techniques, a tool changer allows the robot to change between a vacuum tool, bag tool, clamp tool, and bottom-support tool.

Assembly: Automated assembly tasks may be the most common application for tool changers. Using a tool changer, the robot can switch between various grippers, fastening tools, and sensors.

Deburring: Robotic deburring applications are also one of the largest utilizers of tool changers. Deburring often requires different rotary tools and bits in order to effectively remove burrs from edges, corners, and holes.

Dispensing: Adding a tool changer to a robot in a dispensing application allows the robot to complete part handling (load/unload) between dispensing operations.

Welding: Similar to dispensing, adding a tool changer allows the robot to complete part handling between welding operations.

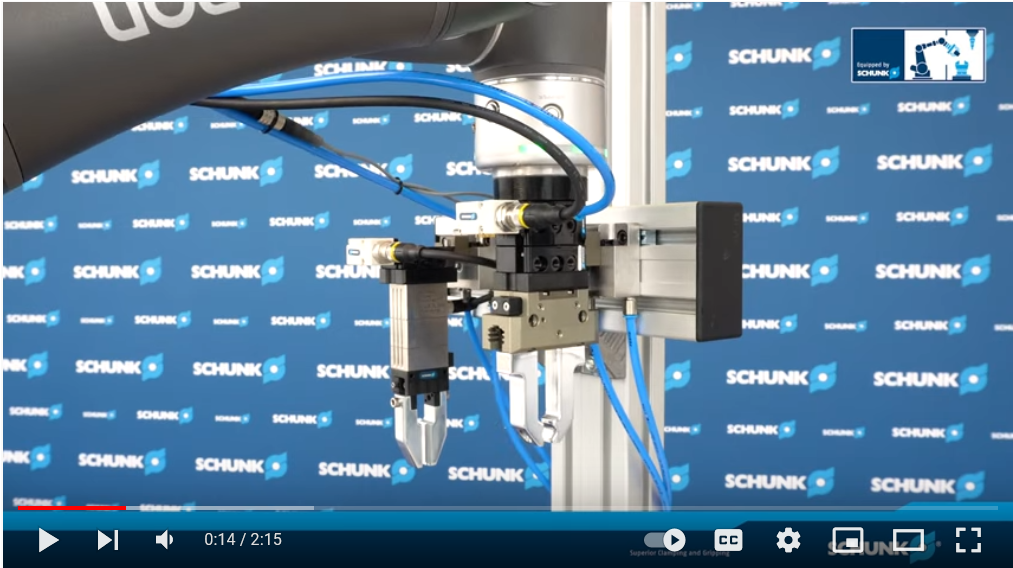

Below are few SCHUNK specific solution-focused examples:

- Assembly processes using mechanical grippers to position different subcomponents into fixturing then switching tools to a robotic fastening tool - welder, adhesive dispenser, screwdriver, nutrunners, rivet gun, etc.

- A similar process for O-rings - mechanical grippers to position parts, then exchanging the tool with an 0-ring gripper to install O-rings.

- Using grippers to load and unload a machining center for primary machining operations, then changing to a robotic material removal tool and have the robot perform the finishing processes (deburring, polishing, etc.).

Special Thanks to Cory Raizor at SCHUNK for co-writing this blog post. For more information on SCHUNK's automatic and manual tool changers, click the links below:

Pneumatic tool changing system with patented locking system

SCHUNK Gripping Systems Product Overview