Baumer Compact Sensor Solutions

Monday, July 11, 2022 4:06:49 PM America/New_York

The mechanical integration of sensors into the machine design is often very demanding and complex. Especially when installation space is tight and the performance requirements for the sensor are high. Learn more about the compact sensors available from Baumer that will save you some headaches during the integration.

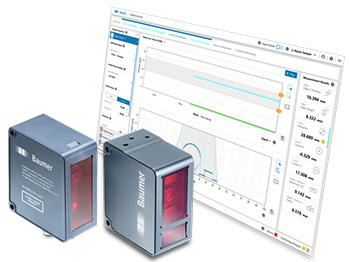

Precise profile comparisons in a compact housing - OXM

Baumer Sensor Applications

| Robot control in container systems - Robot fine positioningThe Baumer OX200 profile sensors guide the robots to the correct position in a container system for rackless storage and handling. The high speed is the key challenge here. The sensor is connected directly to the robot without external software. Signal transmission to the controller takes place via IO-Link in this case. |

|

|

|

|

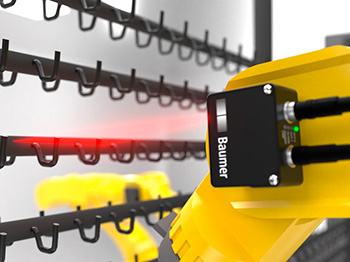

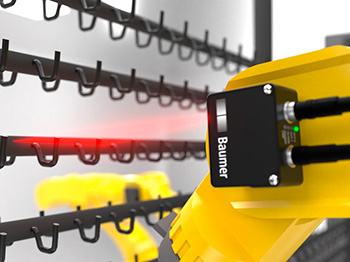

Automated suspension of injection-moulded parts - Robot fine positioning

A Baumer OXM200 sensor measures the position of the hooks on a suspension device and then navigates the robot arm with pinpoint accuracy to the correct position for attaching injection-moulded parts. The compact, lightweight housing and simplified wiring (one-cable solution via Power over Ethernet for power supply and data transmission) ensure the flexibility required at the moving robot arm. Easy integration allows for quick commissioning.

|

|

|

|

|

|

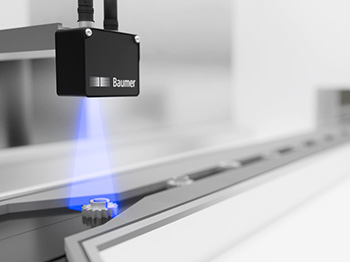

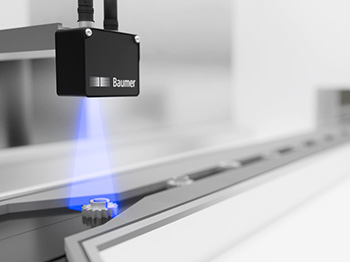

Gearwheel position checks - Inline quality control

The blue laser beam of the OXM200 ensures precise, height-based position control of metal gearwheels during the production process. This makes sure the gearwheels are fed in the correct orientation for optimum subsequent processing. The sensor sends a direct signal to the machine to reject the bad part.

|

|

|

|

|

|

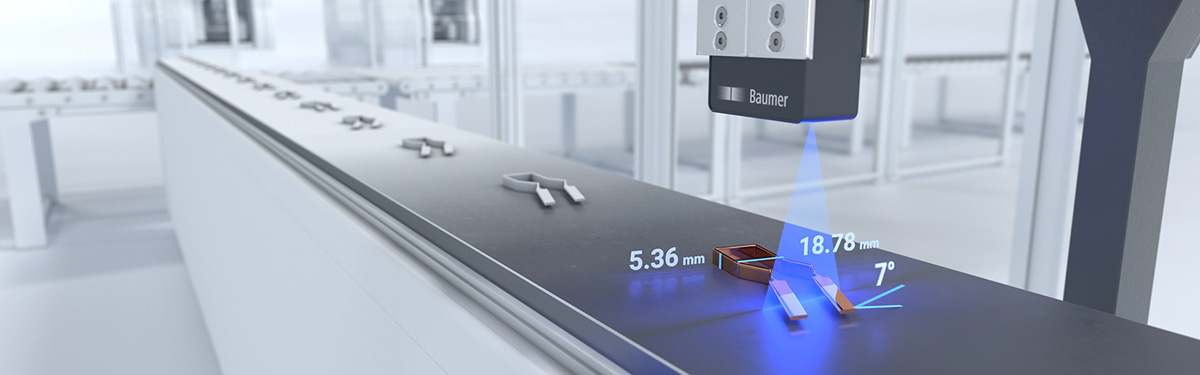

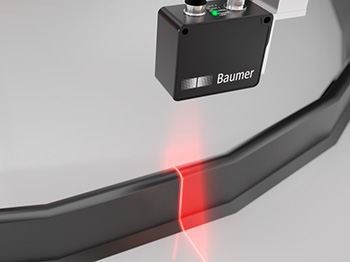

Measurment of the bending angle of a metal object - Inline quality control

Immediately after the bending process, the OXM200 measures whether the bending angle is within the specified tolerance threshold. The measurement result is transmitted directly to the control system thanks to simple data exchange.

|

|

|

|

|

|

Offset measurement of a thin metal film - Inline quality control

In the production process of e-cigarettes, a metal film needs to be wrapped around the cigarettes. During the process, OX100 sensors measure the offset of the 4-mm-thick metal film, completely immune to reflections.

|

|

|

|

|

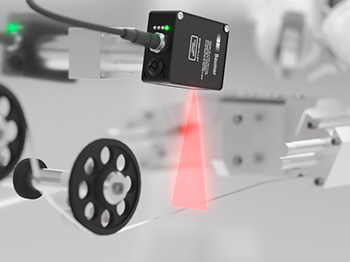

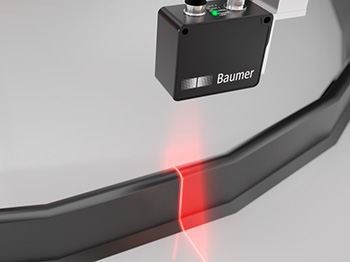

| Height control for dark rubber seals - Inline quality control

Thanks to its extreme reliability even towards dark objects, the OX200 profile sensor allows for non-contact height control of black rubber seals at a very low tolerance threshold of only 2 mm. The solution was not only gentler on the material but also more cost-effective than the tactile measuring instrument used previously.

|

|

Posted in

Electronics

By

Marketing