|

|

Whether you want to automate a simple, repeatable task or need a flexible, intelligent system, Scott Equipment Company has the expertise to develop a solution for your collaborative robot application.

Collaborative robots are becoming more and more popular in the robotic market. This type of robot excels in today's working environment because they work alongside their human counterparts. Collaborative robots are designed with safety features like force feedback and collision detection making them safe to work next to human operators because they drastically reduce the chance of injury shold the robot come into contact with the human.

Pick and Place - Collaborative robots are being used to complete repetitive, montonous tasks because they excel at this kind of functionality. Pick and place robots are usually mounted on a stable stand and strategically positioned to complete their tasks. Pick and place robots perform the following functions:

- Assembly

- Packaging

- Bin Picking

- Inspection

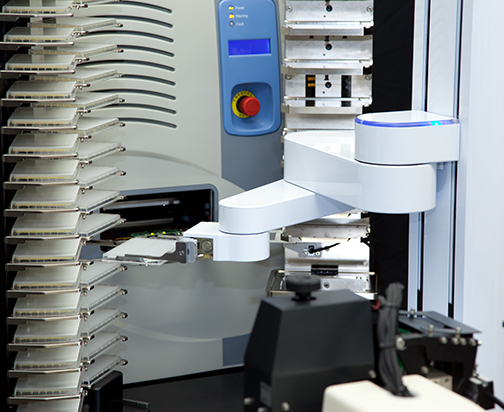

Machine Tending - Machine tending requires a person to stand for long hours in front of a CNC machine, injection-molding machine, or another similar device and tend to its operational needs. This could be tool changes or replacement of raw materials. This process is long and tiresome for the human operator. Not only do collaborative robots free up the operator, but a single robot can also tend to mulitiple machines, leading to increased productivity.

Packaging and Palletizing - Using collaborative robots for packaging and palletizing solves a labor shortage issue, meets the demand for flexible manufacturing, increases productivity, improves consistency and lowers operating costs.

3D Bin Picking - This is the process of of randomly picking parts/items from a bin for production purposes. The robot is connected to a vision system that analyzes the parts/items in the bin and tells the robot which product to select and how to correctly orient the robot to pickup the part/item.

Inspection and Vision - The use of robots equipped with vision sensors to inspect critical and high value parts for quality, contour, surface and dimensional accuracy. This process typically involves the full inspection of finished parts, high resolution images for precision machine parts, and part verification against CAD models. Mounting multiple high-resolution cameras onto cobots can automate the process for faster results. The inspection can also be captured digitally and digitized to compare the image to a computer generated model. Using cobots for inspection can result in higher-quality inspection, resulting in more accurate production batches. End-effectors with high-resolution cameras maybe required for the inspection, as well as vision systems and software.